HONYPRO®ABS profiles is our common plastic profile. ABS resin is one of the five major synthetic resins. It has excellent impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties, as well as easy processing and product dimension stability. , Good surface gloss and other characteristics, easy to paint and color, and can also be subjected to secondary processing such as surface metal spraying, electroplating, welding, hot pressing and bonding. It is widely used in machinery, automobiles, electronic appliances, instruments, and textiles. And construction and other industrial fields, it is a very versatile thermoplastic engineering plastic profile.

ABS profile is made of ABS resin as raw material, extruded and shaped, and the profile with irregular shape is called ABS profile, sometimes also called ABS profile. ABS profiles have excellent impact resistance, heat resistance, low temperature resistance, chemical resistance and electrical properties. Excellent impact resistance of ABS profiles: ABS has excellent mechanical properties, its impact strength is excellent, and it can be used at extremely low temperatures. Good combination: ABS has good combination with other materials, secondary processing such as welding, hot pressing and bonding. Easy to color and spray: can carry out surface metal spraying, electroplating, easy surface printing and other treatments

ABS profile advantages

1. ABS profile is non-toxic and tasteless.

2. It has excellent mechanical properties, its impact strength is very good, and it can be used at extremely low temperatures. ABS profile has excellent wear resistance, good dimensional stability, and oil resistance. It can be used for bearings under medium load and speed.

3. It is not affected by water, inorganic salts, alkalis and many kinds of acids, but it is soluble in ketones, aldehydes and chlorinated hydrocarbons. It will cause stress cracking when corroded by glacial acetic acid and vegetable oil.

4. It has good electrical insulation and is hardly affected by temperature, humidity and frequency. It can be used in most environments.

Good corrosion resistance: ABS is not affected by water, inorganic salts, alkalis and various acids. Good electrical insulation: ABS has good electrical insulation, and is hardly affected by temperature, humidity and frequency, and can be used in most environments. ABS profiles are widely used in the fields of automobiles, electronic appliances, refrigeration, automation equipment, water treatment industries, etc. It is a thermoplastic engineering plastic with a wide range of uses.

ABS profile is made of ABS resin as raw material, extruded and shaped irregular profile. It is called ABS profile, sometimes called ABS profile.

ABS resin is one of the five major synthetic resins. It has excellent impact resistance, heat resistance, low temperature resistance, chemical resistance, and electrical properties. It also has the characteristics of easy processing, stable product dimensions, and good surface gloss. It is easy to paint , Coloring, it can also be used for secondary processing such as surface metal spraying, electroplating, welding, hot pressing and bonding. It is widely used in machinery, automobiles, electronic appliances, instrumentation, textiles and construction and other industrial fields. Wide range of thermoplastic engineering plastics. Acrylonitrile-butadiene-styrene copolymer is a terpolymer composed of acrylonitrile, butadiene and styrene. English name is acrylonitrile–butadiene–styrene copolymer.

Abs Profiles,Abs Plastic Diffuser Extrusion Profile,Colorful Abs Pipe Tube,Shape Extrusion Profile Abs,ABS sheet rod Hony Engineering Plastics Limited , https://www.honyplastic.com

The Proper Way to Use a Gripper

Sure! Here’s the rewritten content in English:

---

A gripper is usually an end-effector attached to the end of a robotic arm or a Cartesian robot, designed to pick up and transfer objects from one place to another. However, simply closing the gripper to clamp an object isn't enough—there's much more to consider, especially when handling delicate items.

In this article, we’ll explore how to effectively grip a load without causing any damage. Let’s dive into the details.

### Challenge

One of the key challenges in robotics is ensuring that a gripper can handle fragile objects gently. For instance, think about gripping something as delicate as a test tube filled with biological samples. In addition to precise positioning, the gripper must adjust its grip force and movement speed dynamically to avoid applying too much pressure or causing any impact that could damage the test tube. While our example focuses on test tubes, the same principles apply to a wide range of sensitive materials.

### Solution

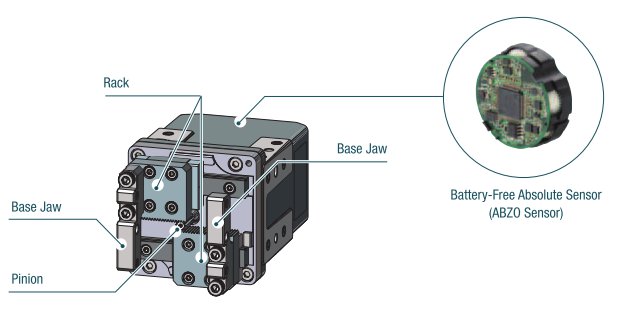

The **EH Series gripper system** provides an innovative solution to this problem. It incorporates a dual-rack-and-pinion mechanism with two base jaws, enabling highly accurate positioning with a repeatability of ±0.02 mm. The standard resolution is 0.02 mm per step, but this can be customized via software. Various gripper arms or "pincers" can be mounted on the base jaws to accommodate different types of loads.

This series also supports multiple driver options tailored to specific needs, including pulse input, RS-485 communication, and various industrial network protocols like EtherCAT and EtherNet/IP. These options make it easier for users to integrate the gripper into their existing systems.

For this discussion, we'll focus on the **Stored Data (RS-485)** driver. This driver allows storage of up to **256 unique motion profiles**, which include position distances, push motions, and speed settings. Once these profiles are programmed using the universal MEXE02 support software, they’re stored directly in the driver. Binary-coded decimal (BCD) inputs can trigger these stored profiles either physically or remotely over an industrial network.

#### What Is Push Motion?

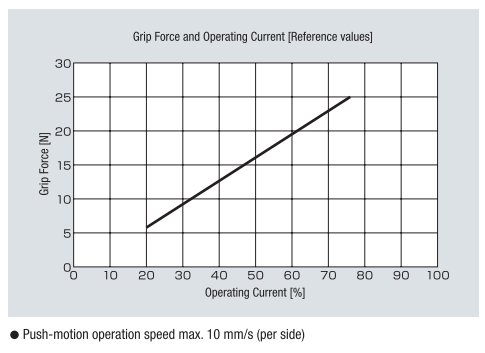

Push motion is a crucial feature that limits the torque of the stepper motor by controlling its current. Since the motor’s torque is directly proportional to its current, precisely regulating the current in **1% increments** enables precise control over the grip force.

### How to Use the EH Series Gripper System Properly

To ensure safe and effective gripping of delicate loads, here are some key points to keep in mind:

- **Use push motion with multiple speed settings**: By combining push motion with variable speed settings, you can significantly reduce impact forces during the gripping process.

- **Linked motion sequences**: The system allows linking multiple motion profiles into one continuous sequence, creating smooth transitions between high-speed approaches and gentle grips.

Let’s visualize this process with an example. Imagine gripping a test tube. First, the gripper moves toward the test tube at a high speed to reach it quickly. As it gets closer, it slows down, approaching the object gently before applying a measured grip force. Once the desired force is achieved, the gripper holds the object securely until it’s released.

#### Example: Soft Load Gripping

Take a look at how push motion works with softer loads like sponges.

Adding variable speed settings enhances the effectiveness further.

Additionally, the mechanical absolute encoder built into the EH Series grippers helps detect the load or confirm its dimensions. The dedicated driver provides useful outputs like TLC, MOVE, and AREA, which can be accessed either physically or remotely via a network connection.

- **TLC Output**: Activates when the desired grip force is reached.

- **MOVE Output**: Indicates when the motor is moving.

- **AREA Output**: Signals when the motor is within a specified position range.

Here’s how this looks in action:

Even without physical wiring, the same operation can be performed using network commands and the handy status monitoring function.

### Conclusion

By integrating push motion, speed settings, mechanical absolute encoder outputs, and driver outputs such as TLC, MOVE, and AREA, you can perform reliable and efficient gripping operations for delicate items. Whether you’re working with test tubes or other fragile loads, the EH Series gripper system ensures precision and safety every step of the way.

If you’d like to learn more about the EH Series grippers or explore additional tools and resources, feel free to check out our related content below. Stay tuned for more updates!

---

I hope this version meets your requirements! Let me know if any further adjustments are needed.