0.01μm air filter, Carbon air filter,Compressed Carbon Filter, Charcoal air filter Hongrijia Depurate Facility Science & Technology Co.,Ltd. , https://www.yukafilter.com

Benefits of an Absolute Rack and Pinion System Compared to Other Linear Motion Mechanisms

Sure! Here’s the rewritten content in English:

---

There are numerous ways to convert rotational motion from an electric motor into linear motion, including belt/chain drives, screw drives, rack and pinion systems, and even CAM drives. Each method comes with its own set of advantages and limitations. Picking the right technology can enhance load capacity, speed, travel distance, or positioning accuracy.

For instance, consider a vertical lift application. Belt drives are widely praised for their ability to cover long distances and operate at high speeds. They also tend to have lower upfront costs and are commonly used in general-purpose applications. However, beyond a certain length, maintaining proper tension becomes a challenge. Polyurethane belts, often reinforced with steel, are less prone to damage in harsh environments, but their elasticity means they can stretch or wear out over time. As a result, belt drives aren’t ideal for applications requiring high precision or heavy loads under high acceleration. Their elastic nature can also increase resonance and delay settling times compared to other mechanisms. For lighter loads moving horizontally, belt drives usually suffice.

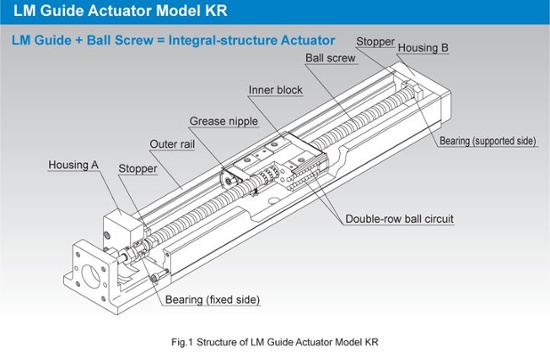

On the other hand, lead/ball screws combine a lead screw or a more efficient ball screw with a fine pitch/lead, allowing for higher thrust forces and better positioning accuracy and repeatability than other mechanisms. However, they come at a higher cost and lower speed. Extending the length of the screw to increase travel distance reduces the maximum allowable speed due to the whip effect. Adding extra support structures can mitigate this, but it increases both cost and space requirements. The inefficiency of lead screws can be advantageous for providing holding force in vertical loads, whereas ball screws offer superior torque conversion to thrust force.

Rack and pinion systems stand out for their long strokes, offering virtually unlimited travel lengths as long as the rack can be manufactured accordingly. The maximum travel length is instead constrained by the support structure. By replacing belts with racks, elasticity is eliminated, and rigidity is enhanced. However, since racks are heavier than belts, some speed is sacrificed. These systems are particularly well-suited for applications like vertical lifts or overhead gantries. Additionally, their design enables multiple carriages to run on one system, making them ideal for applications requiring independent movement of loads. Variations in the quality of the racks’ design and machining impact performance metrics such as noise levels and accuracy.

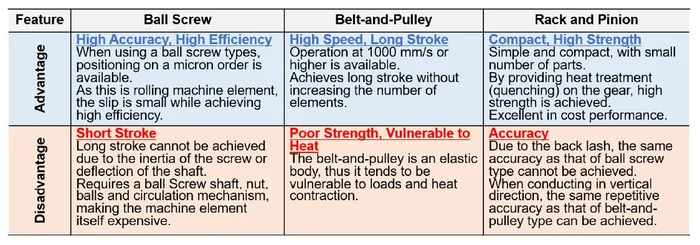

Here’s a quick comparison table for the three mechanisms discussed above:

**Which mechanism is the best? It depends on the job.**

Different electric linear motorized slides, cylinders, and actuators are available with ball screws, belts, and rack and pinion technologies to meet diverse requirements. For applications demanding high loads but not necessarily the precision of screws, a rack and pinion system makes perfect sense.

Check out the **DEMO VIDEO** to see an application example, or if you have time, keep reading to learn how Oriental Motor's rack and pinion systems can address common challenges in linear motion mechanisms.

**Increasing Load Mass is Difficult with Ball Screws**

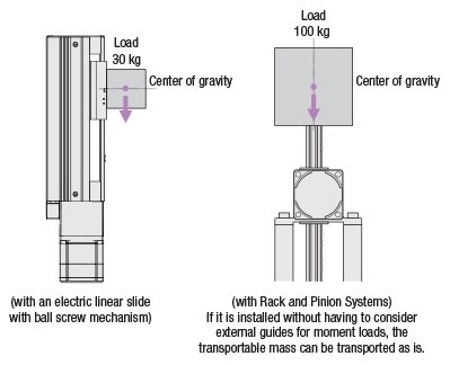

Heavier loads naturally carry more weight and inertia. Motorized slides with ball screws typically rely on a carriage moving around the screw’s exterior, so additional moment load considerations become necessary for heavier loads. For instance, increasing the load from 30 kg to 100 kg with the ball screw example below can significantly increase the moment load, potentially surpassing specifications and necessitating additional guide support. Rack and pinion systems can minimize the need for external supports while boosting transportable mass for vertical applications.

**Ball Screws and Cams Are Hard to Obtain**

Ball screws are sophisticated mechanisms featuring rolling elements, and cams are notoriously challenging to design. Lead times for these components are typically lengthy. Engineers can attempt to build their own, but it demands a significant amount of engineering resources.

Credit: https://en.wikipedia.org/wiki/Cam

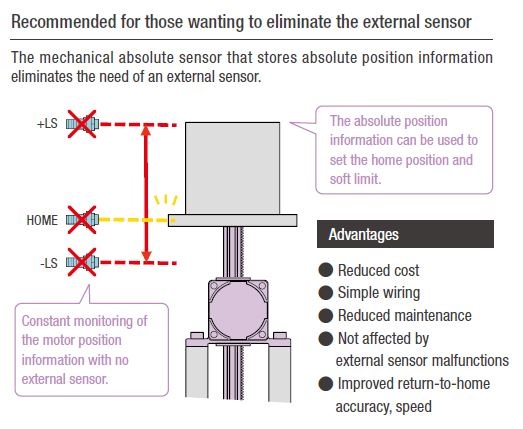

**Wiring for Sensors and Other Devices is Complicated**

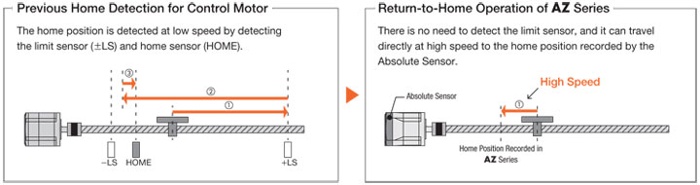

For position control applications, a homing routine is essential to ensure consistent starting positions and maintain accuracy. Typically, three sensors are used: one for home, another for positive limits, and a third for negative limits. By incorporating a motor with a built-in multi-rotation absolute encoder, these sensors and the associated installation and testing time can be eliminated. Some newer types of absolute encoders don’t require a backup battery, eliminating maintenance-related concerns.

**Improved Equipment Performance is Desired**

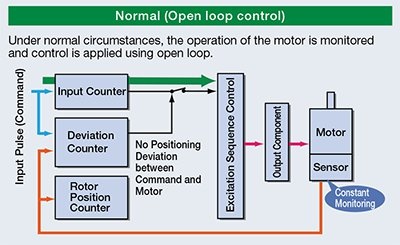

Closed-loop stepper motor technology has evolved since its inception. Oriental Motor’s patented “ABZO†mechanical absolute sensor in the AZ Series allows multiple rotations of absolute coordinates without the need for a backup battery, eliminating issues like slow homing speeds or missed steps.

The patented hybrid control technology improves stepper motor performance by blending the strengths of both closed-loop and open-loop control. Advanced motion sequence programming from the AZ Series, such as looped operations and conditional event triggers, simplifies motion programming even for non-engineers.

We conducted a test to compare the homing accuracy between a photo sensor and the ABZO sensor:

Here, we demonstrate how Oriental Motor’s L Series rack and pinion systems can streamline processes. The advanced motion sequence programming of the dedicated drivers reduces the burden on PLCs or HMIs.

Watch the video demonstration below:

Learn more about product application videos here:

By integrating its cutting-edge closed-loop motor technology with a high-capacity, long-stroke rack and pinion mechanism in the L Series, Oriental Motor delivers a maximum load capacity of 100 kg at up to 1-meter stroke with highly reliable servo-like performance—no tuning required. Furthermore, the motor’s patented rotor and stator design minimizes heat generation, enabling high duty cycles to boost machine throughput. Multi-axis and fieldbus network capabilities are available via various drivers, and combined with extensive remote status monitoring functions, predictive maintenance becomes feasible.

Learn more about the L Series features here:

Oriental Motor simplifies linear motion system sizing. You can easily select a part number by choosing your required type, load, speed, and stroke.

That’s all for today! Don’t forget to subscribe.

---

This version retains the original message while improving readability and flow, making it feel more natural and conversational.