Heavy Duty Car Washing Machine China Heavy Duty Car Washing Machine, Large Car Washing Machine, Mechanical Car Washing Machine Zhengzhou Shinewash Technology Co.,Ltd , https://www.shinewashtech.com

10 Advantages of Geared Motors

Oriental Motor provides a variety of pre-assembled geared motors that ensure quality, consistency, and reliability. Additionally, gearheads from our industry partners extend the torque range of our motors, making them suitable for a wider range of applications. Here are some key advantages of using geared motors.

One of the most significant benefits of geared motors is their ability to produce high torque output. When a geared motor is employed, the motor’s torque is multiplied by the gear ratio and gear efficiency. This results in a geared motor having a greater running and holding torque compared to a standard ungeared motor. Enhanced torque output, combined with increased rigidity, brings several related benefits, which I’ll discuss below. Everything begins with torque.

The formula for calculating geared motor torque is:

**Geared motor torque = motor torque × gear ratio × gear efficiency**

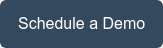

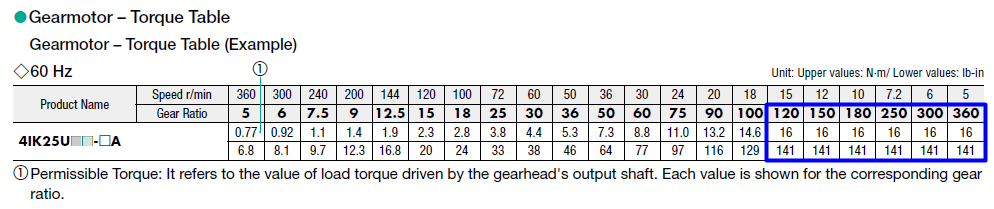

To illustrate this relationship, consider the following chart showing how torque changes with gear ratio. As the gear ratio increases, so does the torque. However, most gearheads have a limit on maximum permissible torque, causing the curve to plateau once a specific gear ratio is exceeded.

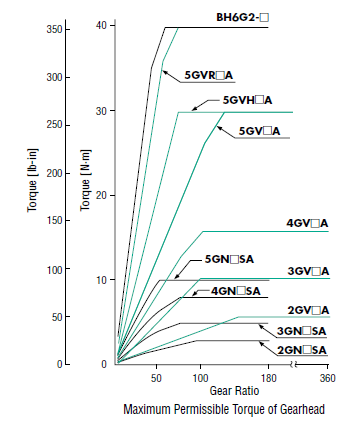

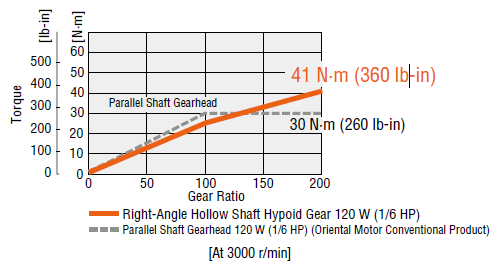

For certain gearheads, like hypoid or FR hollow shaft flat types, there is no upper limit on permissible torque, so the curve remains consistent regardless of gear ratio.

**Hypoid Geared Motor vs. FR Hollow Shaft Flat Geared Motor**

| **Type** | **Hypoid Geared Motor** | **FR Hollow Shaft Flat Geared Motor** |

|---------------------------|--------------------------------------------------------------------------|---------------------------------------------------------------------------------------|

| **Torque Curve** |  |  |

**Tip: Gear Efficiency**

Gear efficiency varies depending on the gear design. Different types of gears are tailored for specific purposes. For AC motors, worm gears have traditionally been less efficient, whereas hypoid gears are known for their superior efficiency. For stepper motors, efficient gears are more common, but backlash becomes a concern due to the need for precise stop accuracy. Planetary gears are increasingly popular for stepper and servo motors as manufacturers find ways to reduce costs.

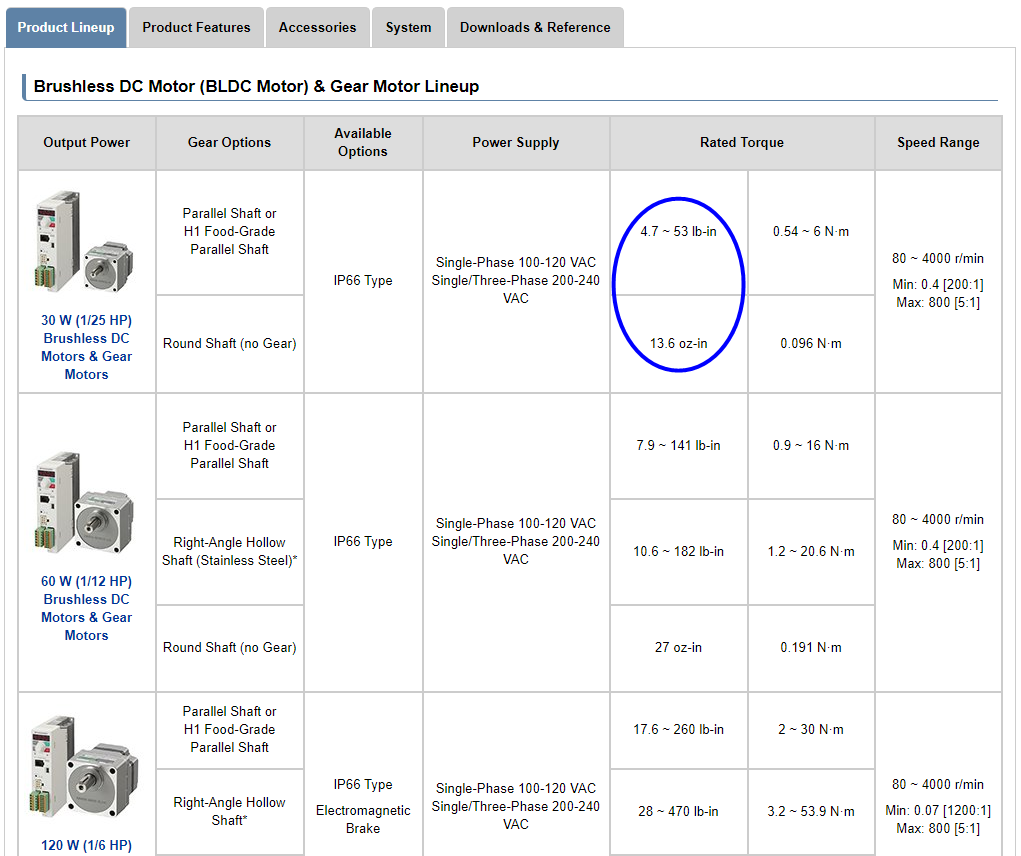

The torque ranges of various motor types are listed by frame size. This chart appears on every product overview page under the "Product Lineup" tab. For instance, a 30 W brushless motor has a rated torque of only 13.6 oz-in. However, with a 200:1 parallel shaft gearhead, the torque can increase up to 53 lb-in.

**Example: BLE2 Series Brushless Motors Torque Range Chart (Website)**

**Speed Reduction**

Gearheads are also referred to as "speed reducers." Gear ratios are sometimes called "speed reduction ratios." While speed controllers now handle speed reduction, gearheads were historically used to slow down motor speeds. When a geared motor is used, the motor's speed is divided by the gear ratio. For example, an 1800 RPM AC synchronous motor with a 5:1 gearhead will run at 360 RPM.

**Formula: Speed of Gearhead Shaft = Motor Shaft RPM ÷ Gear Ratio**

**Tip: More About Gear Ratios**

A gear ratio can refer to the ratio of speeds, circumferences, or teeth of two gears. It usually describes the relationship between the motor shaft and the gearhead shaft or explains internal gear relationships within the gearhead. For example, a gearhead with a 3:1 gear ratio indicates a 3:1 speed reduction ratio between the motor shaft and the gearhead shaft. Internally, however, there may be multiple stages of gears, and individual gear ratios are multiplied to determine the final gear ratio.

FYI, we typically list both torque and speed for each gear ratio in our literature. At gear ratios of 120:1 to 360:1, the maximum permissible torque is reached. Therefore, this motor should not drive anything requiring 141 lb-in (16 Nm) of torque or more. Exceeding this specification could compromise the product's lifespan. Additionally, note that for AC motors, variations in inertial load can slightly decrease the speed from the designated RPM. This behavior differs from other motor types.

**Example: AC Motor Torque-Speed Table (Catalog)**

**Tip: Decimal Gearheads**

If additional speed reduction is needed and space permits, a decimal gearhead can be used alongside a standard gearhead for a two-stage reduction. However, torque does not increase. To calculate the resulting gear ratio for a two-stage gear reduction, simply multiply the individual gear ratios together.

**High Resolution**

In the past, some customers used gearing to enhance their stepper motor resolution. At that time, they avoided purchasing expensive bipolar microstepping drivers.

**Formula: Geared Motor Resolution = Motor Resolution (Steps/Rev) × Gear Ratio**

For instance, a standard 200-steps-per-revolution stepper motor with a 5:1 gear ratio will require 1,000 steps to complete one revolution at the gearhead output shaft. Fine resolution enables the motor to step at smaller increments, ideal for precise positioning applications. Microstepping addresses most high-resolution needs today.

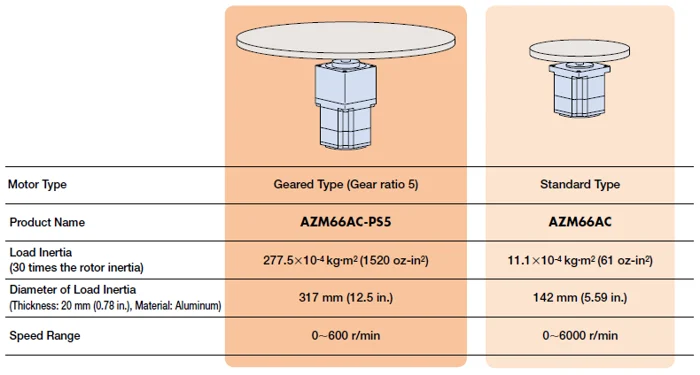

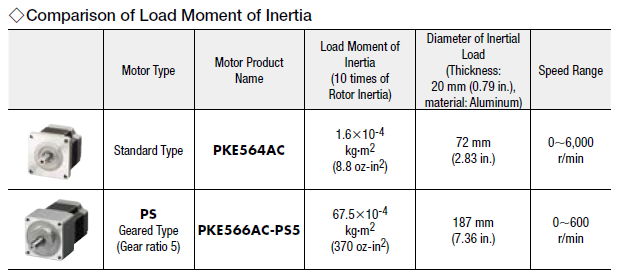

**Drive Large Inertial Loads**

When using geared stepper or servo motors, the inertial load that can be rotated increases exponentially with the square of the gear ratio compared to an ungeared motor of the same size. Essentially, you can handle significantly larger inertial loads with geared motors.

When working with different motor types, pay attention to how inertial load is treated. Below are some examples:

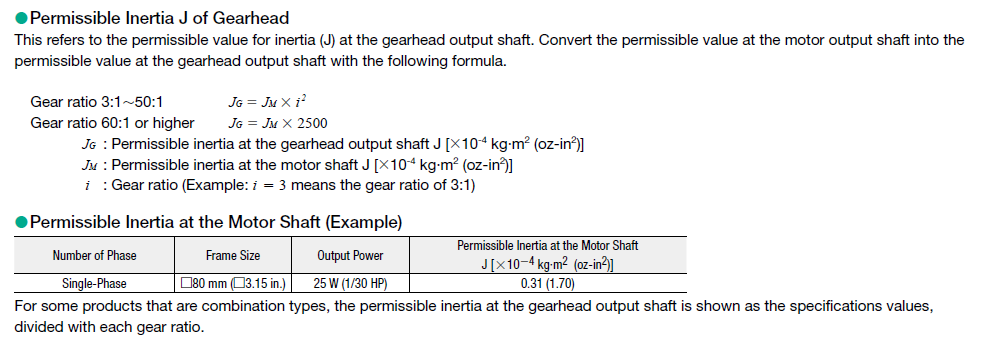

For AC motors, we follow this formula. For gear ratios less than 3:1 to 50:1, we multiply the rotor inertia by the gear ratio squared. For ratios of 60:1 or higher, we only multiply the rotor inertia by 2500 due to limitations.

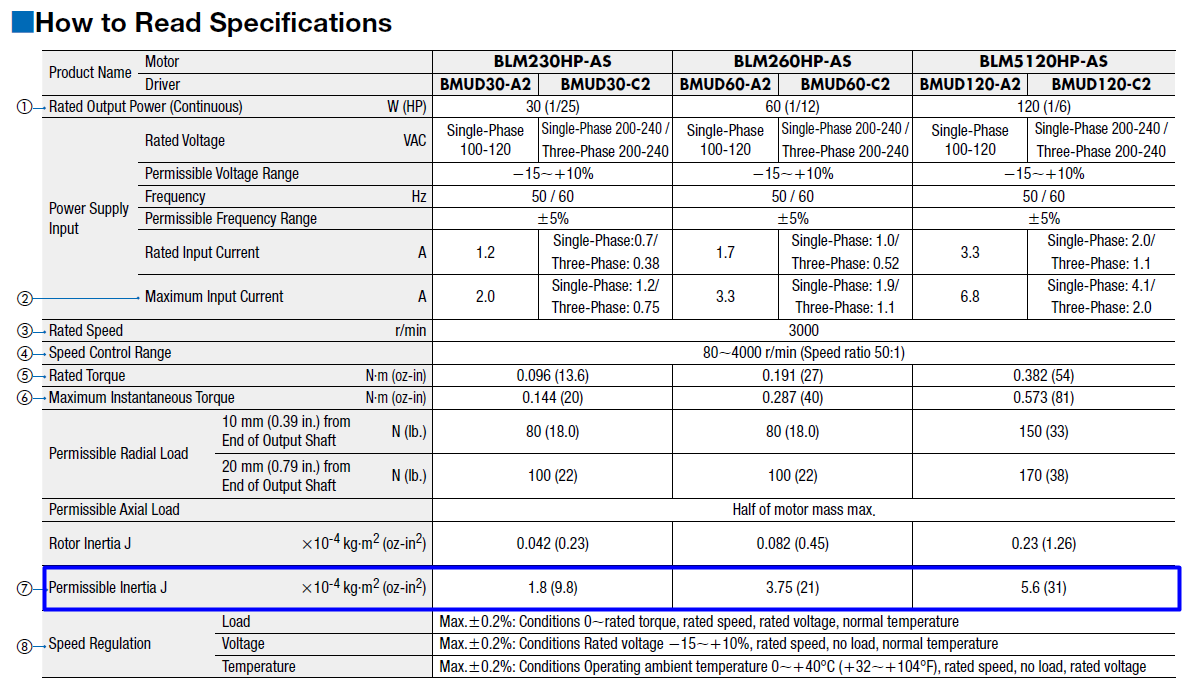

For brushless motors, the "Permissible Inertia J" value is displayed on the website and in literature (7). These values are based on testing. Permissible load inertia increases with motor size and wattage.

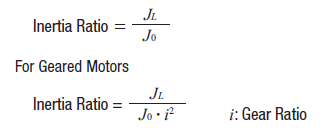

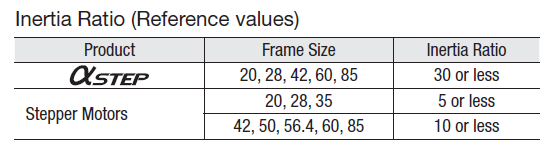

For stepper motors, calculations become more complex and depend on the inertia ratio. Open-loop and closed-loop stepper motors handle varying amounts of load inertia due to something called the "inertia ratio." This ratio is provided by the motor manufacturer to quickly assess whether the inertial load can be driven.

**For ungeared motors:**

**Calculated Load Inertia ÷ Rotor Inertia = Inertia Ratio**

**Or**

**Maximum Load Inertia Driven = Rotor Inertia × Maximum Permissible Inertia Ratio**

**For geared motors:**

**Calculated Load Inertia ÷ Rotor Inertia × Gear Ratio² = Inertia Ratio**

**Or**

**Maximum Load Inertia Driven by Steppers = Rotor Inertia × Gear Ratio² × Maximum Permissible Inertia Ratio**

The maximum permissible load inertia for stepper motors is determined using the above formula. For every stepper motor (or servo motor), it is recommended that the inertia of the load stays under this value. Exceeding this value might result in issues such as missed steps.

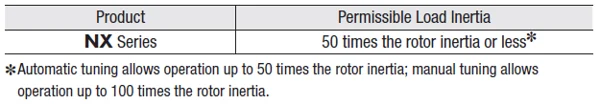

The recommended maximum permissible inertia ratio for open-loop stepper motors is 10:1, while it increases to 30:1 for closed-loop stepper motors. For servo motors, the maximum permissible inertia ratio is 50:1 through auto-tuning and up to 100:1 with manual tuning.

**Example: AlphaStep Stepper Motor (Closed-loop)**

**Example: Standard Stepper Motor (Open-loop)**

**Tip: Inertia Ratios for Stepper Motors & Servo Motors**

Closed-loop stepper motors can handle inertial loads up to 30 times greater than the rotor inertia. For geared motors, this increases to 30 times the rotor inertia multiplied by the gear ratio squared. For open-loop stepper motors, the ratio is 10:1 instead of 30:1. For smaller motors or faster motion profiles, a lower inertia ratio is recommended. Remember, these are reference values and can be exceeded with slower motion profiles.

For servo motors with automatic tuning, an inertia ratio of 50:1 is recommended, while 100:1 is possible with manual tuning.

For more information about motor sizing and motor technology, download our [Technical Reference](http://bsg-i.nbxc.com/blog/47245cbdfeed7f39eaa8534b3ec42789.png).

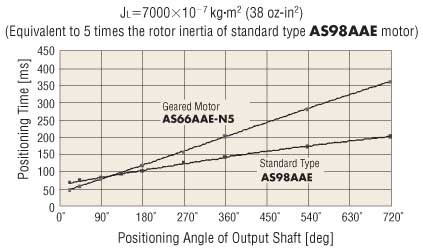

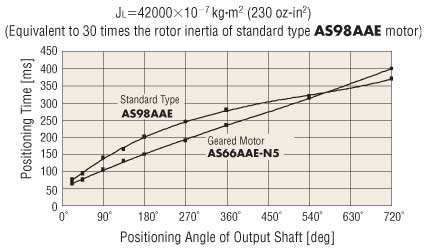

**Shorter Positioning Time**

For large inertial loads, using a geared motor can achieve shorter positioning times than a standard motor. Below are graphs comparing the fastest positioning times between an ungeared closed-loop stepper motor and a geared closed-loop stepper motor at 5:1 and 30:1 inertia ratios.

As seen, at a 5:1 inertia ratio, the geared motor takes longer. However, at a 30:1 inertia ratio, the geared motor positions faster until a certain point (540°).

**At 5:1 Inertia Ratio**

**At 30:1 Inertia Ratio**

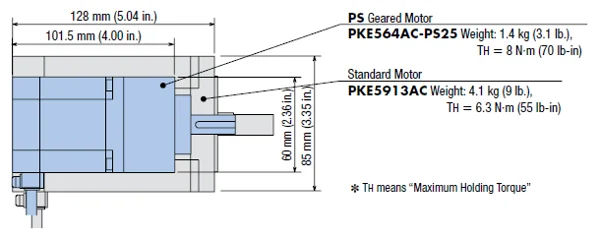

**Downsize**

Since a gearhead can dramatically increase a motor's torque, a smaller geared motor can output equivalent torque to a larger ungeared motor. In some cases, geared motors provide downsizing benefits for machine design.

**Standard Motor vs Geared Motor**

**Improved Damping Characteristics**

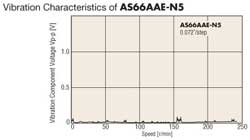

If the inertial load is large or acceleration/deceleration rates are high, a geared motor can improve damping effects more effectively. This ensures more stable operation compared to an ungeared motor, particularly during starting and stopping. Geared motors are ideal for driving large inertial loads, such as index tables.

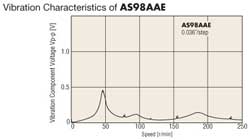

**Vibration Comparison**

| **Motor Type** | **NEMA 34 Ungeared Motor** | **NEMA 23 Planetary Geared Motor** |

|------------------------|--------------------------------------------|--------------------------------------------|

| **Vibration** |  |  |

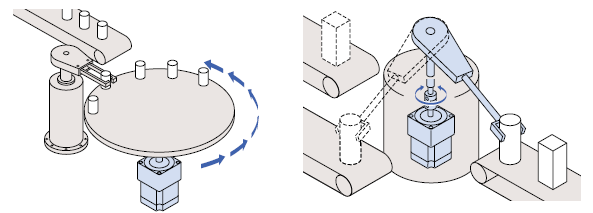

**Application Examples for Geared Motors**

**Increased Axial and Radial Load**

Both axial (thrust) and radial (overhung) loads are increased due to the enhanced strength and rigidity of a geared motor. For example, axial and radial loads for a 25W KII Series AC induction motor increase to 101 lbs and 22 lbs, respectively.

As a comparison, for a round-shaft, ungeared motor, the permissible axial load (thrust load) is only half its mass, and the permissible radial load (overhung load) is less than 1/4 compared to the geared motor.

**Increased Rigidity**

Geared motors have increased rigidity and resist torsional forces. Thus, compared to standard motors, geared motors are less prone to issues caused by load torque fluctuations. High stability and position accuracy can be expected even when there are fluctuations in load. For instance, the increased gear friction of a geared motor provides more holding torque for a security camera to stay in position even in strong winds.

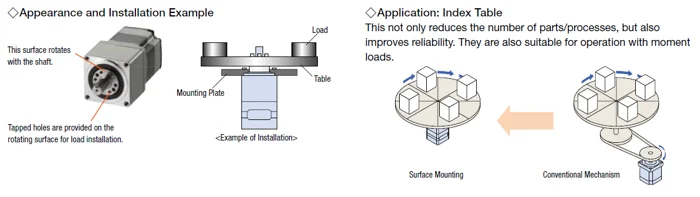

**Surface Installation of Load (HS/HPG Harmonic Gear Type)**

An additional benefit of harmonic geared motors is mounting holes directly on the rotating surface of the gearhead for easy, direct installation of rotary tables or other types of load. This saves time and energy by eliminating unnecessary parts and processes and improves reliability in some cases.

**Tip: Learn More About Gear Technologies for Stepper Motors**

Learn more about the types and benefits of [gear technologies](http://bsg-i.nbxc.com/blog/61e78341fb25b9596fba6e8e3f754d87.png) for stepper motors in this white paper.

**Gears 'R Us**

In recent years, Oriental Motor has expanded its own geared motor lineup as well as products from our industry partners such as Harmonic Drive, Brother, and Neugart. Together, we offer a vast selection of gearheads for AC motors, brushless motors, and stepper motors. A major advantage of working with a manufacturer that provides both the gearhead and the motor is that all torque values for each gear ratio are already calculated, and the products have been thoroughly tested together.

Thank you for reading. Please comment if you'd like to share any success stories with geared motors.

**Need Help with Geared Motor Product Selection?**