Fighting Water Main Breaks with Carbon Fiber Innovations As the summer approaches, many cities in colder climates are dealing with the lingering effects of a severe winter. The record-breaking low temperatures and heavy snowfall have taken their toll, and now, as the mercury rises, new challenges are emerging—like the inevitable water main breaks that plague communities every spring. Known as "water main break season," this phenomenon affects countless areas worldwide. In Prince Albert, Saskatchewan, a continuous water main issue has flooded the streets for over a month, disrupting daily life and local businesses. The Roots of Water Main Breaks One of the primary culprits behind these breaks is the freeze/thaw cycle. When the ground thaws, uneven settling occurs, causing movement under the pipes. Combined with aging infrastructure—some of which dates back nearly a century—the result is an increase in water main failures. This season alone, Prince Albert has experienced 19 such incidents, with more expected in the coming weeks. Local authorities are working on a comprehensive strategy to tackle these problems, recognizing that last winter’s extreme cold placed immense pressure on the city’s underground systems. Battling Corrosion Across North America Corrosion in pre-stressed concrete cylinder pipes (PCCP) costs U.S. water and wastewater networks over $50 billion annually, according to a 2002 study. Across North America, roughly 850 water main breaks occur daily, leading to annual repair expenses surpassing $3 billion. These leaks waste approximately 2.5 trillion gallons of drinking water annually, representing around 17% of all water pumped in the U.S. Shockingly, 90% of this wastage stems from corrosion-related issues tied to outdated pipes. A 2012 Utah State University study found that 43% of American water mains are between 20 and 50 years old, while another 22% have exceeded that threshold. Unfortunately, nearly half of the one million miles of pipelines beneath our streets are nearing the end of their useful lives. Experts estimate that replacing them will cost over $1 trillion in the next 25 years. Given the current lack of sufficient funding, it’s critical that we find ways to extend the lifespan of our existing PCCP infrastructure. Revolutionizing Pipe Repairs with HJ3’s CarbonSeal HJ3’s CarbonSeal carbon fiber technology offers a practical solution to these pressing issues. Consider a case where a coal-fired power plant faced a crisis: a 120-inch diameter pipe responsible for supplying water to its cooling towers had developed cracks in its internal concrete lining. Water infiltrating through these cracks caused significant corrosion of the pre-stressed wires inside. As these wires weakened, the pipe lost its ability to handle internal hoop stress. Rather than opting for costly full-scale replacement, the plant chose HJ3’s CarbonSeal system to repair the 750-foot stretch of pipe. How CarbonSeal Works The repair process began with an abrasive cleaning of the pipe’s surface, followed by injecting polyurethane foam into any leaks. Next came priming the surface before applying the saturated CarbonSeal carbon fabric layer by layer. A protective topcoat ensured a seamless, pinhole-free finish, making the system entirely impermeable. Amazingly, the entire repair took just 11 days, restoring the pipe’s structural integrity. This method saved 50% compared to traditional repair techniques and slashed costs by 65% relative to replacement. Additionally, it prevented six tons of concrete from being discarded in landfills. After eight years in operation, the system continues to perform flawlessly, meeting expectations. The client praised HJ3 for their exceptional support during the project, particularly in designing calculations, creating detailed engineering plans, handling termination specifics, and providing on-site oversight. Learn More About CarbonSeal Reinforcement If you’re facing similar challenges with underground pipes and want to explore HJ3’s CarbonSeal solutions further, reach out to them directly at [insert contact information]. †††Timing Cover,Front Timing Cover,Timing Chain Cover,Timing Belt Cover Ningbo Maixun International Trade Co., Ltd , https://www.nbmachinery.com

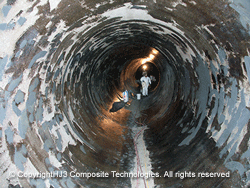

![PNM-1[1]](http://bsg-i.nbxc.com/blog/0cea1ad9232aeaed06638a149fc83342.jpeg)