Laser Carving & Cutting Machine Laser Carving & Cutting Machine,Fabric Laser Cutting Machine,Cnc Laser Cutting Machine,Laser Cutting Machine Metal HT-Metalforming Equipment Manufacturing Co.,Ltd , https://www.htmetalforming.com

What Determines Motor Life?

Understanding how to use a product effectively can significantly impact its performance and longevity. For instance, proper care for cast iron pans can extend their lifespan considerably. Similarly, with electric motors, recognizing the factors influencing motor life is crucial for prolonging its operational time and reducing costs over the long term.

To begin with, what exactly marks the end of a motor's life? Typically, end of life refers to when a product ceases to function as per its specified parameters. Even if the motor is still operational, if it can no longer meet its stated specifications—such as speed, torque, or accuracy—it essentially becomes unusable to us.

**Key Factors Affecting Motor Lifespan**

The lifespan of any product often depends on the first component that fails. For electric motors, three primary components are most susceptible to failure: bearings, gears, and circuitry elements like drivers and controllers.

### Bearings

Bearings are essential components that minimize unwanted movement and reduce friction between moving parts. In a motor, they support the load shaft and rotor. Damage to these bearings halts motor operation, making them critical for continued functionality.

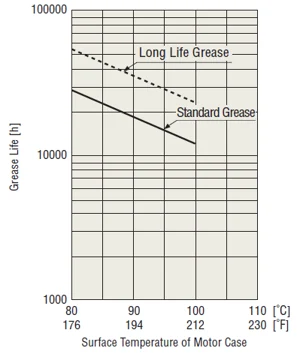

Standard motor lifespans are generally estimated based on the lifespan of the bearing grease, which is highly sensitive to temperature changes. Exceeding motor specifications, such as excessive radial or axial loads, can also shorten its life. Motors equipped with long-lasting bearing grease can operate up to around 10,000 hours.

### Gears

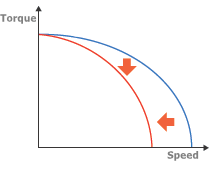

Gears play a vital role in reducing motor speed while increasing torque. The torque multiplication depends on the gear ratio, and speed decreases accordingly. Like bearings, gears handle significant loads and can wear out over time, particularly under impact loads or when specifications are exceeded. Once worn, while the motor may still function, it will produce increased noise and reduced precision.

### Circuit Products

Circuit products, including drivers and controllers, supply power and logic to stepper or servo motors. Components within these systems, such as electrolytic capacitors, can degrade due to high temperatures. The lifespan of these circuit products is tied to the lifespan of their electrolytic capacitors.

**How Does Temperature Influence Lifespan?**

Temperature plays a critical role in determining the longevity of motors. Several factors, including insulation degradation, sliding components, and bearings, contribute to motor wear. In most cases, motor lifespan hinges on bearing life, which itself is governed by grease life, which is heavily influenced by temperature. Rolling fatigue also impacts bearing life but not as significantly as temperature. Using long-lasting grease can extend bearing life.

An increase in bearing temperature by 15°C (27°F) cuts its lifespan in half. It’s essential to manage temperature increases for both grease and electronic components. For instance, an electrolytic capacitor’s lifespan halves when ambient temperatures rise by 10°C (18°F).

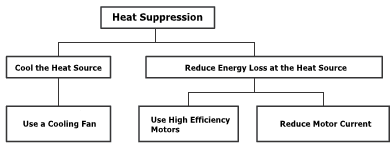

**Strategies to Control Temperature Rise**

There are two primary ways to manage temperature rise in motors: cooling the heat source and minimizing heat generation. Cooling methods include using fans, heat radiation (mounting to larger metal plates), and efficient heat dissipation. Lowering motor operating temperatures extends bearing grease life, enhancing overall motor longevity. It also allows for higher duty cycles. In one case, I assisted in implementing a water-cooled jacket that nearly doubled the stepper motor’s duty cycle.

Alternatively, reducing energy loss at the motor also curtails temperature rise. Energy loss manifests as heat, so cutting down on losses cools the system. High-efficiency or continuous-duty motors achieve this. For stepper and servo motors, reducing current lowers temperature, as current is directly proportional to heat. However, current is also linked to torque, so it’s best to adjust current to a level that provides sufficient torque while keeping temperatures as low as possible.

Thank you for reading! If you found this insightful, consider subscribing. For further details on how temperature impacts service life, rated life for various products, and actual calculations for service life, refer to the technical reference section of our catalog.

If you're interested in our cooling fans, high-efficiency motors, or methods to reduce current, feel free to reach out to our technical support team. They’re always ready to help!

---

Looking forward to your feedback and happy engineering!