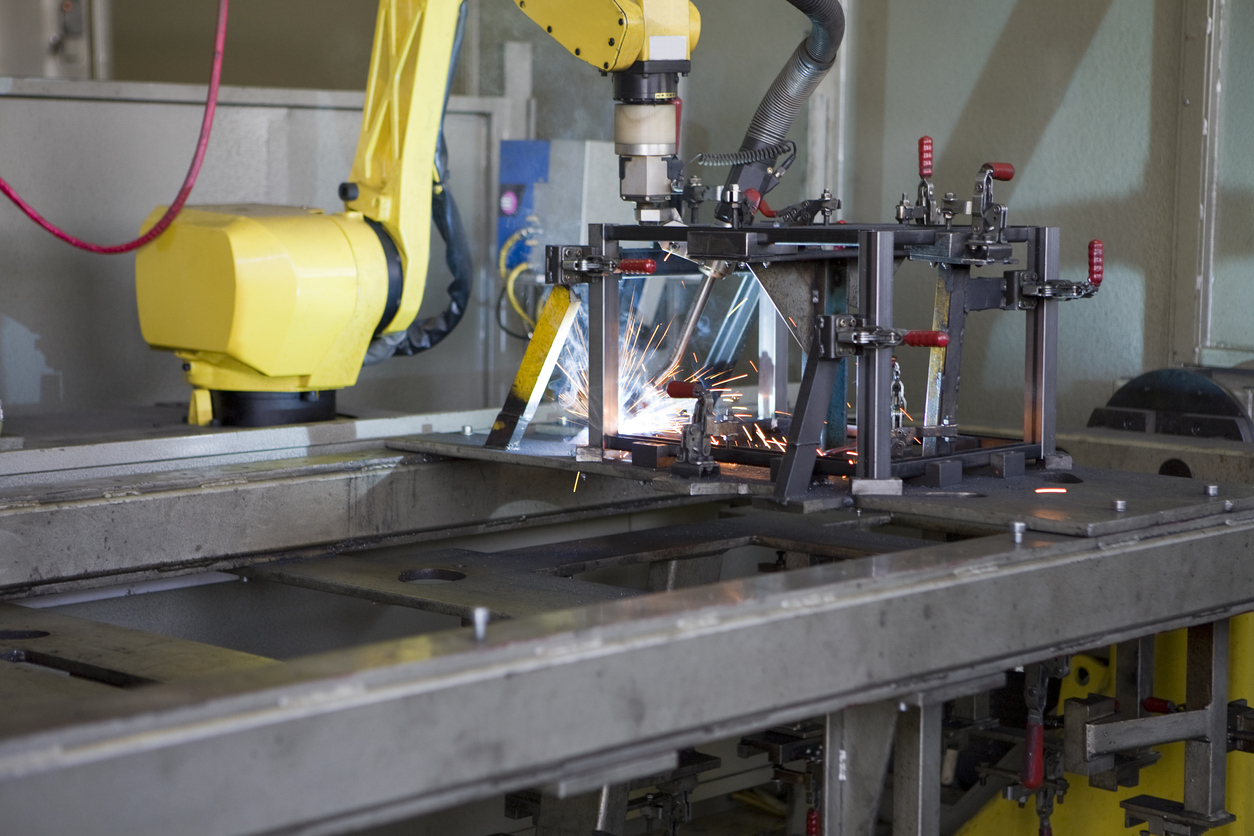

Robotic welding sensors are becoming an essential part of modern manufacturing. They provide the robot with additional information about the workpiece, the weld quality, and even allow it to learn from past errors. This added intelligence can significantly improve the flexibility, accuracy, and efficiency of a robotic welding system. With so many types of sensors available on the market, it can be challenging to determine when it’s worth investing in them and which type is most suitable for your application. There are several key factors to consider before making a decision. As robotic welding has evolved and become more widespread across various industries, different sensor technologies have been developed to address common challenges. Here are some of the most commonly used types: While there are many other sensor types available, these three are among the most widely used in robotic welding systems today. Investing in robotic welding sensors is typically most beneficial in environments with high part variety, where the robot must perform multiple complex tasks. Large or irregularly shaped parts that are difficult to locate accurately also benefit greatly from sensor integration. If the way parts are presented to the robot changes frequently and cannot be resolved through tooling or fixtures, sensors become essential for achieving consistent and repeatable results. However, the key factor to consider is the return on investment. Sensors should only be implemented if the productivity gains they provide justify the initial cost. For more insights into how robotic welding sensors can enhance your production line, explore robotic welding integration services offered by industry leaders like Genesis Systems. With over 35 years of experience, Genesis has helped thousands of companies implement efficient and reliable robotic welding solutions. Can cooler cover water bottle,can cooler cover water,foam can cooler cover Huaian Boshi Sports Products Co.,Ltd , https://www.cnboshisports.comKnowing When to Use Sensors for Robotic Welding

Types of Robotic Welding Sensors

When Is It Worth Investing in Robotic Welding Sensors?