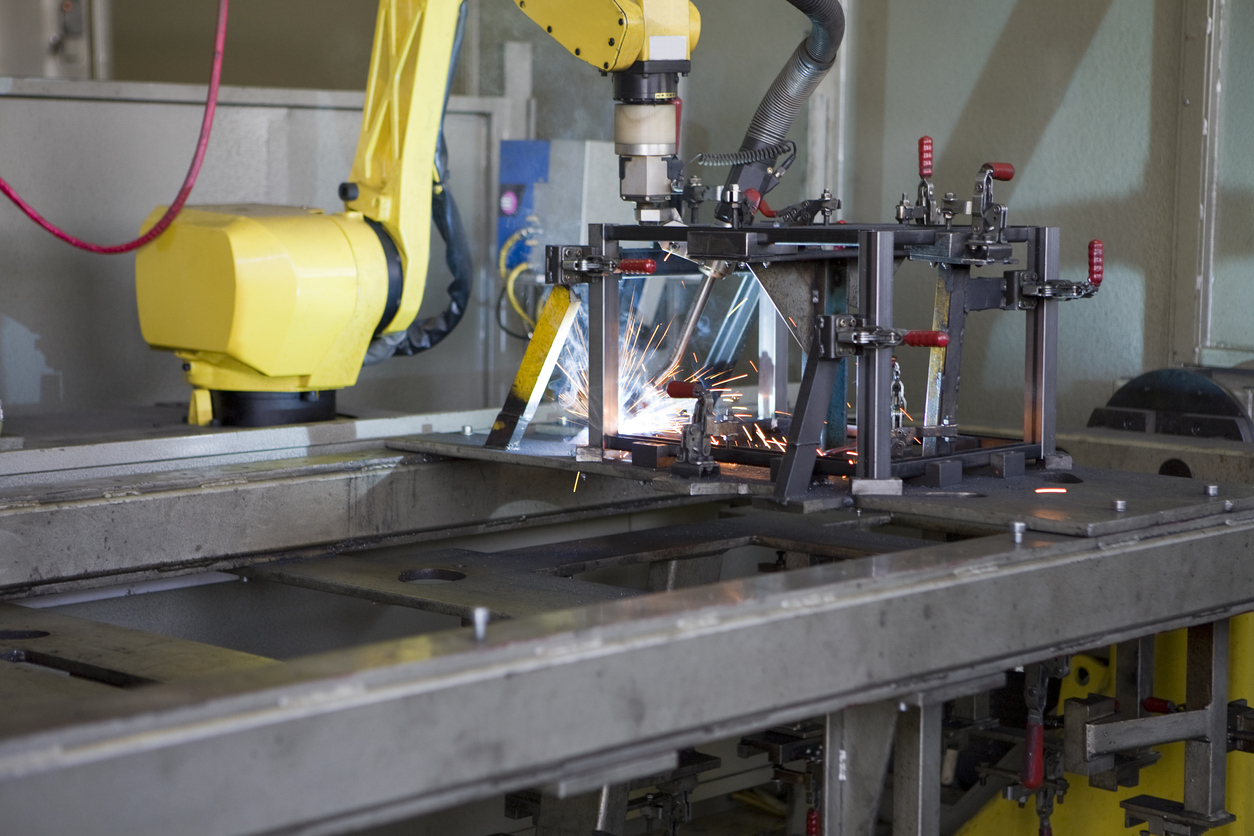

Robotic welding has revolutionized manufacturing by improving speed, precision, and consistency. However, even the most advanced robotic systems can benefit from additional tools that enhance their performance. One such tool is the use of sensors—devices that provide critical feedback and help robots adapt to real-world conditions. Sensors play a key role in increasing the flexibility and accuracy of robotic welding systems. By providing real-time data on part positioning, weld quality, and system performance, these sensors enable robots to make adjustments on the fly, leading to better results and fewer reworks. But with so many sensor types available, it's important to understand when they're truly needed and which ones will offer the best return on investment. As robotic welding has become more widespread across various industries, different sensor technologies have been developed to address specific challenges. Here are some of the most common types used today: While there are other types of sensors available, these three are among the most widely used in robotic welding applications. Investing in robotic welding sensors is typically most beneficial in situations involving high part variability or complex geometries. If your production line handles multiple part designs or large, irregularly shaped components, sensors can significantly improve accuracy and reduce setup times. Additionally, if the way parts are presented to the robot changes frequently and cannot be reliably managed by fixtures or tooling, then sensors become a necessity. The key factor in deciding whether to invest is the expected return on investment. If the productivity gains from using sensors outweigh the initial cost, then it's a smart move. If you're looking to explore how robotic welding sensors can benefit your operations, consider consulting with an expert in robotic integration. Companies like Genesis Systems have over 35 years of experience helping manufacturers implement efficient and reliable robotic welding solutions. Their expertise can guide you in choosing the right technology for your specific needs. Surfing Suits,Swim Wetsuit Surf,Wetsuit Shorts Surf,Sleeveless Wetsuit Surf Huaian Boshi Sports Products Co.,Ltd , https://www.cnboshisports.comKnowing When to Use Sensors for Robotic Welding

Types of Robotic Welding Sensors

When Does It Make Sense to Invest in Robotic Welding Sensors?