8 Types of Cap Screws and Their Applications

Cap screws are fasteners that feature either internal or external socket drive heads, with different shapes depending on the type. Below the head, they have a fully or partially threaded shaft with a beveled end. These fasteners are commonly used in machinery, automotive, and industrial manufacturing due to their high yield strength and durability.

Table of contents

- Different Types of Cap Screws and Their Applications

- Mechanical Properties and Grades of Socket Head Cap Screws

- ASTM Standards of Cap Screws

- Socket Cap Screw Sizes as per ASME B18.3

- Hexagon Socket Head Screws Size Chart (BS 2470)

- Button Head Cap Screws Dimension

- Recommended Tightening Torque for Button Head Screws

- Advantages of Using Cap Screws in Machine Parts and Clamping

- How To Measure An Allen Head Socket Cap Bolt

- Shank and Thread Length Measurements for Allen Head Cap Bolts

- Torque Specs For Socket Head Cap Screws

- Cap Screw Applications

- Knurled Head Cap Screws Certification

- Cap Screws Metric DIN and ISO Standards

- Cap Screws vs Socket Screws

- Manufacturing Process of Socket Head Cap Screws

Different Types of Cap Screws and Their Applications

| Type of Cap Screw | Head Shape | Drive Type | Application | |

|---|---|---|---|---|

| Flat Head Cap Screws |  |

Countersunk | Hex or Socket | Used where a flush surface is needed, such as in countersunk holes |

| Hex Head Cap Screws |  |

Hexagonal | Hex or Socket | Heavy machinery and structural applications |

| Socket Head Cap Screws |  |

Cylindrical | Hex Socket | Precision applications where space is limited |

| Button Head Cap Screws |  |

Rounded | Hex or Socket | Where a low profile is needed or for aesthetic purposes |

| Pan Head Cap Screws |  |

Rounded with a flat underside | Hex or Socket | General-purpose use where a large bearing surface is required |

| Slotted Hex Cap Screws |  |

Hexagonal | Slotted or Hex | Applications where a slotted screwdriver is preferred |

| Torx Cap Screws |  |

Star-shaped | Torx | High-torque applications |

| Low Head Socket Cap Screws |  |

Low-profile cylindrical | Hex Socket | For applications with limited vertical space |

| Hex Flange Cap Screws |  |

Hexagonal with a flange | Hex or Socket | Automotive and machinery applications |

| Tri-Wing Cap Screws |  |

Triangular winged | Tri-Wing | Security applications |

Flat head cap screws are manufactured according to ISO 4762 standard

Mechanical Properties and Grades of Socket Head Cap Screws

| Grade | Strength | Tensile Strength (MPa) | Yield Strength (MPa) | Equivalent SAE Grade |

|---|---|---|---|---|

| 8.8 | Medium strength | 800 | 640 | 5 |

| 10.9 | High Strength | 1000 | 900 | 8 |

| 12.9 | Very High Strength | 1200 | 1080 | 9 |

ASTM Standards of Cap Screws

- ASTM F835 (Alloy Steel Flat Countersunk and Socket Button Head Cap)

- ASTM F912M (Alloy Steel Socket Set Screws (Metric))

- ASTM F912 (Alloy Steel Socket Set Screws)

- ASTM F837M (SS Socket Head Cap Screws (Metric))

- ASTM F837 (SS Socket Head Cap Screws)

Round socket head screws are available in a wide range of sizes

Also known as round head cap screws or circle head screws, these fasteners are extremely useful in various applications. They are often used in electronics, construction, carpentry, and fastening thin materials. Due to their unique shape, they offer a secure and durable connection, making them ideal for many industrial and mechanical uses.

They are also known for their toughness and can be used as security fasteners. Without the proper tools, it can be difficult to install or remove them. In construction, they are cost-effective and provide good value for money. In carpentry, they are easy to use and suitable for woodworking projects.

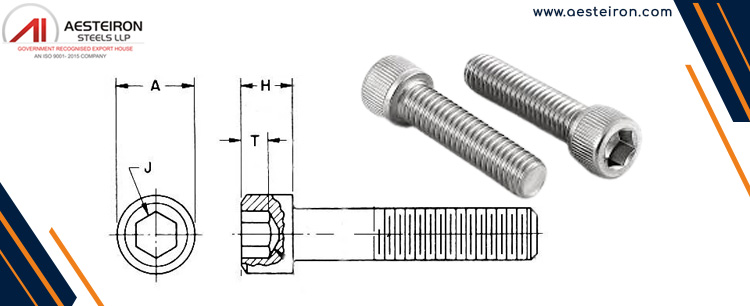

Socket Cap Screw Sizes as per ASME B18.3

| Thread Size | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 01/4 | 5/16 | 03/8 | 7/16 | 01/2 | 05/8 | 03/4 | 07/8 | 1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T.P.I UNF | 80 | 72 | 64 | 56 | 48 | 44 | 40 | 36 | 32 | 28 | 24 | 24 | 20 | 20 | 18 | 16 | 14 | 12 |

| T.P.I UNC | Â | 64 | 56 | 48 | 40 | 40 | 32 | 32 | 24 | 20 | 18 | 16 | 14 | 13 | 11 | 10 | 9 | 8 |

| Head Dia (Max) A | 0.096 | 0.118 | 0.14 | 0.161 | 0.183 | 0.205 | 0.226 | 0.27 | 0.312 | 0.375 | 0.469 | 0.562 | 0.656 | 0.75 | 0.938 | 1.125 | 1.312 | 1.5 |

| Key Engagement (Min) T | 0.025 | 0.031 | 0.038 | 0.044 | 0.051 | 0.057 | 0.064 | 0.077 | 0.09 | 0.12 | 0.151 | 0.182 | 0.213 | 0.245 | 0.307 | 0.37 | 0.432 | 0.495 |

| Head Height (Max) H | 0.06 | 0.073 | 0.086 | 0.099 | 0.112 | 0.125 | 0.138 | 0.164 | 0.19 | 0.25 | 0.312 | 0.375 | 0.438 | 0.5 | 0.625 | 0.75 | 0.875 | 1 |

| Key Size J | 0.05 | 1/16 | 5/64 | 5/64 | 3/32 | 3/32 | 7/64 | 9/64 | 5/32 | 3/16 | 01/4 | 5/16 | 03/8 | 03/8 | 01/2 | 05/8 | 03/4 | 03/4 |

| Thread Length (Max) | 0.62 | 0.77 | 0.8 | 0.83 | 0.99 | 1 | 1.05 | 1.19 | 1.27 | 1.5 | 1.71 | 1.94 | 2.17 | 2.38 | 2.82 | 3.25 | 3.69 | 4.12 |

| Thread Length (Min) | 0.5 | 0.62 | 0.62 | 0.62 | 0.75 | 0.75 | 0.75 | 0.88 | 0.88 | 1 | 1.12 | 1.25 | 1.38 | 1.5 | 1.75 | 2 | 2.25 | 2.5 |

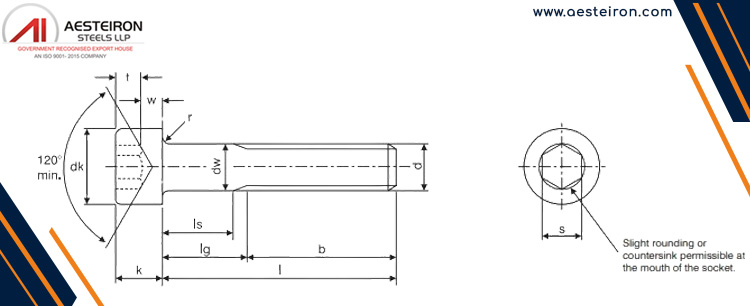

Hexagon Socket Head Screws Size Chart (BS 2470)

| Nominal size and thread dia d | Â | 0 | 2 | 1 | 3 | 5 | 4 | 6 | 10 | 8 | 12 | 5/165/16 | 1/41/4 | 3/83/8 | 43467 | 43593 | 7/167/16 | 43528 | 43654 | 43528 | 1 | 1.1/4 | 1.1/8 | 1.3/8 | 1.3/4 | 1.1/2 | 2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Head dia dk | max.max. | 0.096 | 0.14 | 0.118 | 0.161 | 0.205 | 0.183 | 0.226 | 5/165/16 | 0.27 | 0.343 | 7/167/16 | 3/83/8 | 9/169/16 | 43528 | 0.812 | 5/85/8 | 43654 | 1.1/8 | 1 | 1.5/16 | 1.75 | 1.5 | 1.875 | 2.5 | 2 | 2.75 |

| min.min. | 0.093 | 0.136 | 0.114 | 0.157 | 0.2 | 0.178 | 0.221 | 0.306 | 0.265 | 0.332 | 0.429 | 0.367 | 0.553 | 0.739 | 0.795 | 0.615 | 0.863 | 1.111 | 0.987 | 1.297 | Â | Â | Â | Â | Â | Â | |

| Pitch of thread | UNC | — | 56 | 64 | 48 | 40 | 40 | 32 | 24 | 32 | 24 | 18 | 20 | 16 | 13 | 12 | 14 | 11 | 9 | 10 | 8 | 7 | 7 | 6 | 5 | 6 | 4.1/2 |

| UNF | 8000% | 6400% | 7200% | 5600% | 4400% | 4800% | 4000% | 3200% | 3600% | 2800% | 2400% | 2800% | 2400% | 2000% | 1800% | 2000% | 1800% | 1400% | 1600% | 14-Dec | 1200% | 1200% | 1200% | – | 1200.00% | – | |

| Thread length b | min.min. | 0.5 | 0.625 | 0.625 | 0.625 | 0.75 | 0.75 | 0.75 | 0.875 | 0.875 | 0.875 | 1.125 | 1 | 1.25 | 1.5 | 1.625 | 1.375 | 1.75 | 2.25 | 2 | 2.5 | Â | Â | Â | Â | Â | |

| Dia of unthreaded shank dw | max.max. | 0.6 | 0.086 | 0.073 | 0.099 | 0.125 | 0.112 | 0.138 | 0.19 | 0.164 | 0.216 | 0.3125 | 0.25 | 0.375 | 0.5 | 0.5625 | 0.4375 | 0.625 | 0.875 | 0.75 | 1 | 1.25 | 1.125 | 1.375 | 1.75 | 1.5 | 2 |

| min.min. | 0.0568 | 0.0822 | 0.0695 | 0.0949 | 0.1202 | 0.1075 | 0.1329 | 0.184 | 0.1585 | 0.21 | 0.3053 | 0.2435 | 0.3678 | 0.4919 | 0.554 | 0.4294 | 0.6163 | 0.8647 | 0.7406 | 0.98861 | 1.2336 | 1.1086 | 1.3568 | 1.7295 | 1.4818 | 1.978 | |

| Width across flats s | nom.nom. | 0.05 | 1/161/16 | 0.05 | 5/645/64 | 3/323/32 | 5/645/64 | 3/323/32 | 5/325/32 | 1/81/8 | 5/325/32 | 7/327/32 | 3/163/16 | 5/165/16 | 43532 | 43532 | 5/165/16 | 43467 | 43724 | 43724 | 43593 | 43528 | 43528 | 43528 | 1.1/4 | 1 | 1.3/8 |

| Thickness of head k | max.max. | 0.06 | 0.086 | 0.073 | 0.099 | 0.125 | 0.112 | 0.138 | 0.19 | 0.164 | 0.216 | 5/165/16 | 1/41/4 | 3/83/8 | 43467 | 0.562 | 7/167/16 | 43593 | 43654 | 43528 | 1 | 1.25 | 1.125 | 1.375 | 1.75 | 1.5 | 2 |

| min.min. | 0.057 | 0.083 | 0.07 | 0.095 | 0.121 | 0.108 | 0.134 | 0.185 | 0.159 | 0.201 | 0.306 | 0.233 | 0.368 | 0.492 | 0.553 | 0.43 | 0.616 | 0.864 | 0.74 | 0.988 | 1.236 | 1.111 | 1.36 | 1.734 | 1.485 | 1.983 | |

| Radius under head r | max.max. | 0.007 | 0.008 | 0.007 | 0.008 | 0.01 | 0.009 | 0.01 | 0.014 | 0.012 | 0.014 | 0.017 | 0.014 | 0.02 | 0.026 | 0.03 | 0.023 | 0.032 | 0.044 | 0.039 | 0.05 | Â | Â | Â | Â | Â | Â |

| min.min. | 0.003 | 0.004 | 0.003 | 0.004 | 0.006 | 0.005 | 0.006 | 0.009 | 0.007 | 0.009 | 0.012 | 0.009 | 0.015 | 0.02 | 0.022 | 0.018 | 0.024 | 0.034 | 0.03 | 0.04 | Â | Â | Â | Â | Â | Â | |

| Wall thickness w | min.min. | 0.019 | 0.028 | 0.023 | 0.032 | 0.04 | 0.036 | 0.044 | 0.061 | 0.052 | 0.074 | 0.1 | 0.08 | 0.12 | 0.16 | 0.18 | 0.14 | 0.2 | 0.28 | 0.24 | 0.32 | 0.475 | 0.428 | 0.523 | 0.665 | 0.57 | 0.76 |

| Hex socket depth t | min.min. | 0.025 | 0.038 | 0.031 | 0.044 | 0.057 | 0.051 | 0.064 | 0.09 | 0.077 | 0.11 | 0.151 | 0.12 | 0.182 | 0.245 | 0.276 | 0.213 | 0.307 | 0.432 | 0.37 | 0.495 | 0.62 | 0.557 | 0.682 | 0.87 | 0.745 | 0.995 |

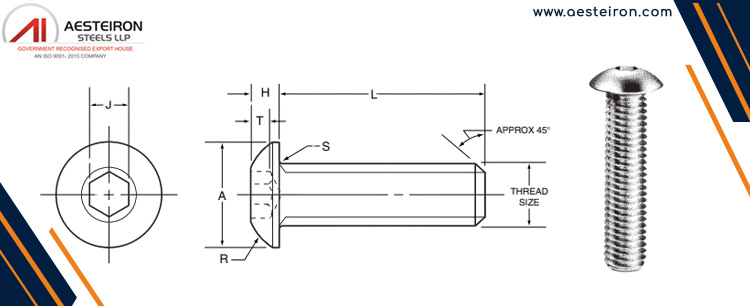

Check dimensions and tensile strength of button head cap screws

It has the similar shape of a pan head with the driver of a socket head. It is manufactured for fastening applications, it doesn’t have strength like standard socket screws. The socket driver is perfect for low withdrawal applications which needs a large area of clamping face.

Moreover, the button heads socket drive gives higher strength than a standard phillips which gives fitting in tight area. It has low domed head with a broader bearing surface heads, which offers a finished look. It is ideal choice when accurate appearance is required.

Button Head Cap Screws Dimension

| Nom thread size | Â | M3 | M4 | M5 | M6 | M8 | M10 | M12 | *M16 |

|---|---|---|---|---|---|---|---|---|---|

| pitch | Â | 0.5 | 0.7 | 0.8 | 1 | 1,285 | 1.5 | 1.75 | 2 |

| max | A | 5.7 | 7.6 | 9.5 | 10.5 | 14 | 18 | 21 | 28 |

| max | H | 1. Shrinkable Tape Closure Patch,Anti Corrosion Fix Patch,Heat Shrinkable Tape Fix Patch,Fiberglass Reinforced Closure Patch SICHUAN FOREVER RADIATION TECHNOLOGY CO.,LTD , https://www.fieldjointscoatings.com |