In previous ventilation plans, people often decided which product and quantity to use based on the number of air changes in the space. In a small space, this effect is very obvious, and you can even see with your own eyes that the steam in the bathroom is quickly discharged to the outside with the operation of the Negative Pressure Fan. However, in tall and spacious enclosed spaces, the effect of this ventilation is not obvious: the relatively large proportion of smoke, moisture, carbon dioxide, and poor quality air are still concentrated at the bottom of the building, and the negative pressure fan on the roof has no effect on the air in all corners, while personnel and equipment are there. A super large energy-saving fan will promote air mixing throughout the entire space, allowing for the removal of foul smelling smoke. Moisture is well dispersed and absorbed, thereby improving indoor air quality and creating a healthy, dry, and safe working environment. Logistics center high-pressure fan, high-pressure fan, logistics high-pressure fan Julai (Chongqing) ventilation equipment Co.,Ltd , https://www.julaifans.com

Design Recommendations for Central Inverters in Utility-Scale Solar Projects

When developing large-scale solar energy projects, optimizing central inverters is an often-overlooked yet vital component that project developers, EPCs, and stakeholders frequently neglect. Properly positioning and designing central inverters can significantly enhance the efficiency and output of utility-scale solar photovoltaic (PV) power systems. Neglecting these aspects not only results in unnecessary material costs but also decreases system efficiency. This can lead to reduced power generation and, in some cases, higher voltage drops throughout the system.

### Strategic Approaches to Central Inverter Placement and Design

#### Physical Placement Considerations:

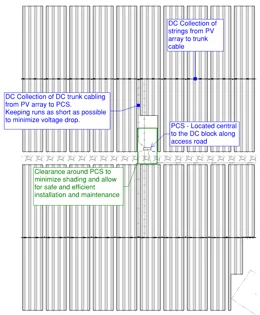

- **Accessibility and Maintenance:** Placing central inverters near access roads within the solar farm is a smart decision. This setup makes it easier for operation and maintenance (O&M) teams to perform their duties and simplifies the construction process.

- **Equidistant DC Strings:** Ensuring each DC string is positioned equidistant from the inverter minimizes voltage drops across individual strings. This even distribution helps maintain the overall efficiency of the power conversion process.

- **Height Considerations:** During the design phase, it’s important to account for the height of the Power Conversion System (PCS). PCS units can be tall when placed on elevated pads, potentially causing shading that reduces the efficiency of solar PV panels.

- **Pad Selection:** Choosing the right pad type is critical. Options include Concrete Pads, Steel Piles, Helical Steel Piles, Ground Screws, etc., depending on the specific conditions of the site.

#### Electrical Design Details:

- **Proximity to Roads:** Positioning the medium voltage part of the inverter close to access roads allows the electrical circuitry to run parallel to the medium voltage pathways, reducing complexity and potential interference with other circuits.

- **Inverter Loading Ratio (ILR):** The ILR, which compares the reduced AC size of the PCS to its DC size, should be greater than 1.0. Maintaining an ILR higher than this threshold ensures the PCS operates optimally, meeting the Point of Interconnection (POI) requirements.

- **Load Flow Analysis:** Conducting a detailed load flow analysis is essential to verify that the expected power delivery aligns with the utility's terms. It also confirms whether the installed inverters can meet the power demand, preventing possible penalties from utilities for under-delivery.

For those looking for comprehensive engineering solutions for utility-scale, commercial, and industrial solar and energy storage projects, Pure Power Engineering stands out as the go-to provider. Our experienced team of engineers and project managers has successfully managed thousands of major solar and storage projects, making us industry leaders. We offer a full range of utility-scale engineering services tailored to every stage of your project lifecycle, including development engineering with up to 10% optimization, project engineering at key milestones (30%, 60%, and 90%), structural engineering and pole design, power engineering studies, glare studies, and on-site inspections and capacity testing.

To learn more about our Utility-Scale Solar + Storage engineering services, visit [www.PurePower.com](http://www.PurePower.com) or contact us at info@PurePower.com.