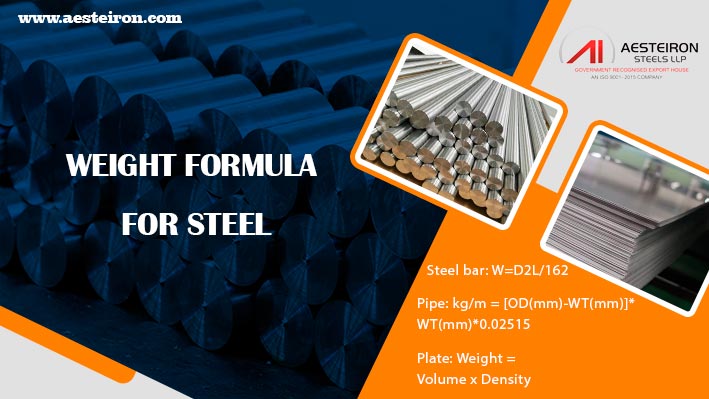

Table of contents The table below provides accurate weight values for different steel sizes, making it easier to estimate materials for your project. Steel Bar Weight Chart Weight Chart of Bars per Bundle Steel Plate Weight Chart Weight of Steel Bars Formula Steel Bars Weight = D²/162 Where, D2/162 Formula Derivation Weight of Steel Bar (W) = Unit Weight of Steel Bar (γ) x Volume (V) W = γ x V 7850 kg/m3 (γ) = Steel unit weight W = πD²/4 x 7850 Steel diameter in mm will be converted to m to create a constant value in the same unit D² mm / 1000² The following table shows the weight of steel per meter, which is useful for various applications. Steel Unit Weight Per Kg Factors Influencing Steel Beams Weight Calculation 1] Beam Size and Shapes 2] Beam Length 3] Steel Grade and Density: 4] Additional Load 5] Connections and Joints Steel Pipes Weight Formula Steel pipes = W = 0.02466 x D^2 x L / 10202 Where, W = steel pipe weight in kg/m Eg: Steel Bars Tolerance Steel Types and its Density Steel Weight in Feet Titanium Gate Valve is a commonly used valve type used to control fluid flow. It is made of titanium alloy material and has excellent corrosion resistance, high strength, and lightweight properties, making it widely used in various industrial fields. Titanium Gate Valve,Casting Valve,Titanium Alloy Gate Valve,Manual Titanium Gate Valve Baoji Qiyuexin Metal Material Co., Ltd. , https://www.qyxtitanium.com

Calculate bars and plate weight using formula

Size MM

Â

8

10

12

16

BIS Standard KG/MTR.

min

0.367

0.574

0.844

1.501

avg

0.395

0.617

0.888

1.58

max

0.423

0.66

0.932

1.659

Values Kg/Mtr.

Â

0.375 to 0.400

0.580 to 0.620

0.850 to 0.910

1.510 to 1.600

Size MM

20

25

28

32

BIS Standard KG/MTR.

2.396

3.734

4.685

6.121

2.47

3.856

4.83

6.31

2.544

3.964

4.975

6.499

Values Kg/Mtr.

2.400 to 2.510

3.750 to 3.910

4.700 to 4.900

6.184 to 6.436

Steel Bar Size (mm)

8

10

12

16

20

25

28

32

Steel Bar pieces per bundle (No.s)

10

7

5

3

2

1

1

1

Length of Steel Bar (M)

12

12

12

12

12

12

12

12

Total Weight of Steel Bar bundle (Kg)

45

48.72

51

54.36

57.6

45

56.4

74.21

Plate Thickness

(mm)

1.6

2

2.5

3

3.2

4

5

6

8

10

12.5

15

20

22.5

25

30

32

35

40

Weight

(kg/m2)

12.6

15.7

19.6

23.6

25.1

31.4

39.3

47.1

62.8

78.5

98.1

118

157

177

196

236

251

275

314

Plate Thickness

(mm)

45

50

55

60

65

70

75

80

90

100

110

120

130

150

160

180

200

250

Weight

(kg/m2)

353

393

432

471

510

550

589

628

707

785

864

942

1051

1178

1256

1413

1570

1963

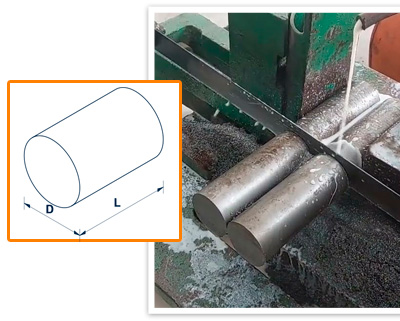

Check the formula to calculate weight of steel

D = Diameter

162 is a constant value

Consider,

Diameter = D

Length = L

W = πD²/4 x γ (V = πD²/4)

steel dia in mm

density = kg/m3

W = π/4 x D²/1000² x 7850

W = D²/162.28 kg/m

W = D²/162 kg/mRefer unit weight of steel per kg

Unit Weight Of Steel

Size

6 mm

8 mm

10 mm

12 mm

16 mm

20 mm

25 mm

32 mm

Kg/m

0.222 kg

0.395 kg

0.617 kg

0.89 kg

1.58 kg

2.47 kg

3.86 kg

6.32 kg

View the factors which influence weight calculation of Steel Beams

Calculate the weight of steel pipes using below formula

D = steel pipe OD in mm

L = steel pipe length in m

Consider,

steel pipe OD (D)= 100 mm, length (L) = 6m

W = 0.02466 x 100^2 x 6 / 10202

W = 0.02466 x 10000 x 6 / 10202

W = 1480 / 10202

W = 0.145 kg/m

Nominal Size (mm)

Â

Over 10 upto and including 16

Up to and including 10

Over 16

Tolerance On

Batch

± 5

± 7

± 3

The Nominal

Individual Sample

-6

-8

-4

Mass, Percent

Individual Samples for Coils Only

± 6

± 8

± 4

Steel type

Carbon steel

Tool steel

Wrought iron

Carbon tool steel

Cold-drawn steel

Density (kg/m³)

7840

7715

7750

7820

7830

Steel type

C1020 HR steel

Pure iron

Mild steel

Stainless steel

Density (kg/m³)

7850

7860

7870

8030

Size

6 mm

8 mm

10 mm

12 mm

16 mm

20 mm

25 mm

32 mm

Kg/feet

0.067 kg

0.120kg

0.188 kg

0.270 kg

0.480 kg

0.751 kg

1.174 kg

1.925 kg

The main feature of titanium alloy gate valves is to control the flow of fluids by moving the gate up and down. When the sealing surface of the gate and valve body is parallel, fluid can pass through; When the gate moves downwards, the sealing surface gradually adheres to the valve seat, causing the fluid to be completely cut off. This design enables titanium alloy gate valves to have advantages such as good sealing, low fluid resistance, and flexible switching.

Titanium alloy gate valves are suitable for special working environments such as high temperature, high pressure, corrosive and toxic fluids. They are commonly used in fields such as chemical engineering, oil and natural gas, ocean engineering, aerospace, etc. Titanium alloy gate valves are widely used in marine and deep-sea mining, nuclear industry, pharmaceutical industry and other special fields.

The design and specifications of titanium alloy gate valves are diverse to meet the requirements of different fluids and working conditions. Its size range ranges from small pipeline connections to large industrial equipment. In addition, titanium alloy gate valves can also be customized according to specific application requirements to adapt to various process requirements and environmental conditions.

Overall, titanium alloy gate valves are widely used in the industrial field due to their excellent corrosion resistance, high strength, and lightweight characteristics. They play an important role in fluid control and process regulation, ensuring the reliability and safety of the system.